Concrete Repair Dallas can be a difficult job. Many variables are involved, and the product must be placed correctly to provide a long-term solution. A qualified contractor will have experience with different repair methods, and can evaluate the structure to determine whether it is major or minor damage.

A successful repair depends on material properties including cracking resistance, permeability and freeze-thaw durability. The surface must also be thoroughly clean and moist to allow the new concrete to bond with existing concrete.

Concrete structures are subjected to extreme and varied environmental conditions, including freeze-thaw cycles and water and chemical penetration. Over time, these elements cause concrete to deteriorate, leading to cracking and the eventual need for repair. Cracks can be shallow and easily repaired, or they may extend across the entire structure and be more difficult to correct.

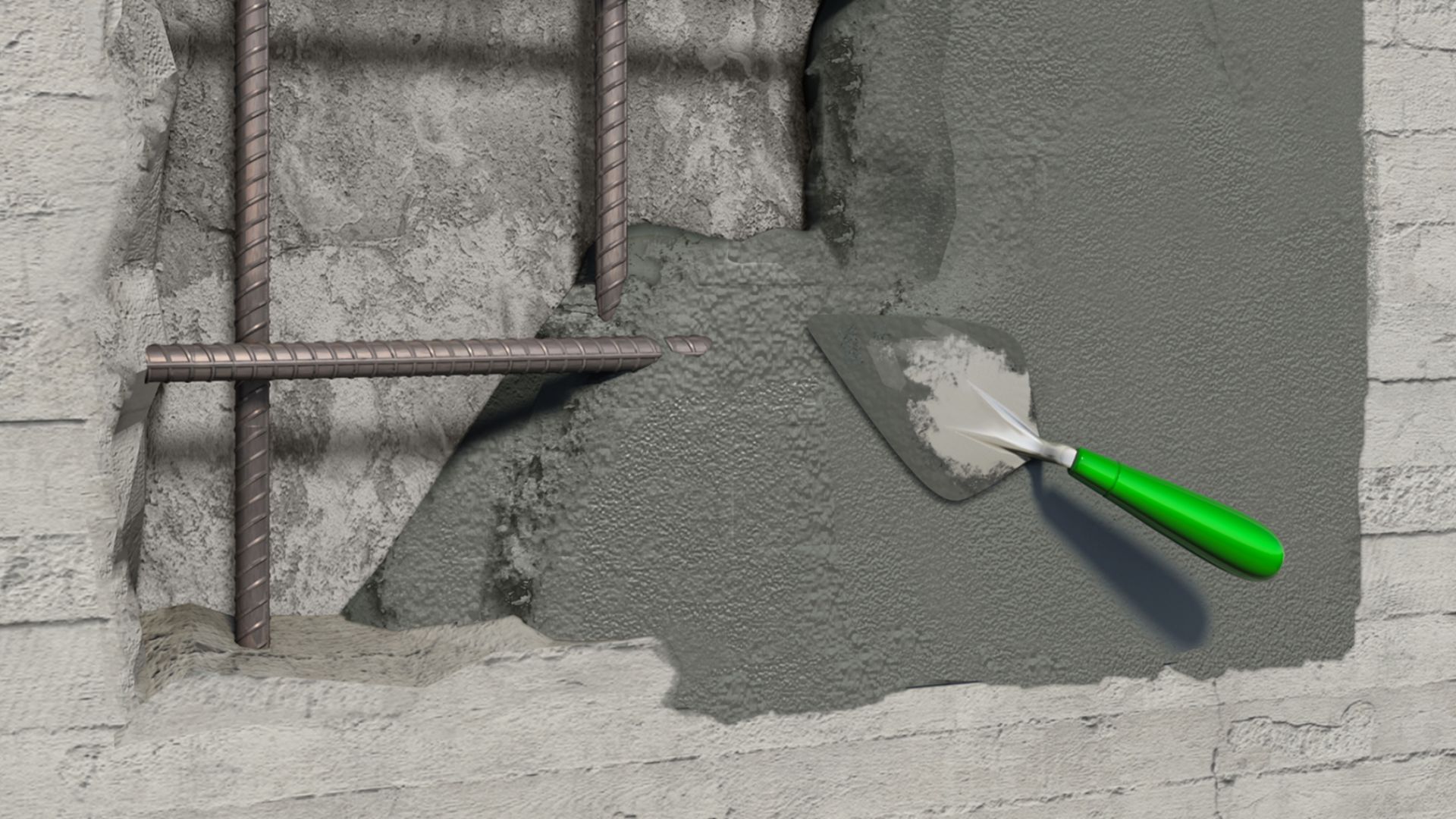

Preparation of the damaged area is one of the most important aspects of any concrete repair project. This involves cleaning the area to be repaired, removing any loose debris and dust, and ensuring that it is free of contaminants such as oil, grease and metal. Concrete is often contaminated with these materials from the surrounding environment and from equipment used during construction. This contamination must be removed before beginning the repair process.

In addition to removing contaminants, surface preparation can also include etching the concrete or applying a chemical bonding agent, depending on the type of repairs being performed. Bonding agents improve the adhesion of new concrete to existing concrete. They are especially useful for repairing concrete that is not structurally sound, such as a cracked or spalling concrete surface.

There are several different concrete repair methods available, the most common being spraying epoxy into the crack. This method is useful for reestablishing tensile strength in active cracks, as it prevents the cracks from moving further, and helps to reduce leakage. It is also a good choice for repairing large areas of degraded concrete, as it can be applied quickly and is relatively inexpensive.

Drilling and plugging is another popular method of repairing concrete cracks, and can be very effective in preventing further movement of cracks. This method involves drilling a hole the length of the crack and then filling it with grout or epoxy. This creates a grout key, which locks the crack and prevents further movement.

Other concrete repair methods can involve sawing or grinding the concrete, brushing it clean, and then spraying it with epoxy. This is a common method of repairing cracks in sidewalks and driveways, as it is quick and relatively inexpensive.

Concrete repair requires a variety of materials. The most important are bonding agents, fillers and sealants. The type of damage and service conditions will determine the repair material and method to be used. In most cases, a concrete repair product that is suitable for the crack or defect must be selected before beginning work.

When selecting a concrete repair material, it is necessary to consider the type of crack or defect, whether the crack is active or dormant, and the type of application (structural versus non-structural). For structural repairs, a repair material with sufficient strength, durability and low drying shrinkage should be chosen to ensure that the injected repair is not weaker than the adjacent concrete. The permeability of the repair material should be low to prevent the penetration of aggressive substances that could corrode embedded reinforcement.

For non-structural repairs, a repair material with sufficient flexibility is required to allow for future crack movements without damaging the surrounding concrete or the repair. The hardness or stiffness of the repair material is also an important consideration. For slabs, a repair material with higher hardness provides greater load bearing capacity and crack edge support, but may be less flexible.

The chemical properties of the repair material are also an important factor to consider. Ideally, the repair material should have a low pH and be compatible with the existing concrete/structure and its constituents. The sulphate and chloride content of the concrete should also be taken into account as these can affect the performance of the repair material.

Finally, the ease with which the concrete repair products can be applied and cleaned is an important factor to consider. Some require specialized equipment and technical expertise, while others are easy to use by almost anyone.

For example, a latex-based concrete repair product is good for filling cracks up to 3/8″ deep and 1/2″ wide and is easy to clean up with acetone or similar chemicals. However, a polyurethane-based crack repair product is better suited for large, deep and wide cracks due to its superior bond and durability.

The #1 reason concrete repair work fails is poor preparation. It’s like a dentist who rents a shabby office and picks up a sharp instrument; it takes expert workmanship and specialized tools working in tandem to deliver a smile-worthy result. In the same way, you must take proper safety precautions, plan ahead and consider professional help when necessary, and choose products that are designed for the conditions where your repairs will occur.

The first step is to ensure your work area is clean and free of debris. It may be helpful to use a pressure washer or power grinder. You should also check your chosen concrete repair product’s specifications for surface prep recommendations.

You’ll also need to have some basic hand tools such as a utility knife, small hammer and a wire brush. If you are repairing holes, a chisel and pry bar might be needed as well. Other useful tools include a scraper and a rake to clean out the hole and prepare the concrete. You should also have a level and tape to mark the height you wish to achieve.

Once the repair area is prepared, mix the concrete patching material according to the product’s instructions. It’s important to follow these directions carefully for the best results.

Concrete patching products that are fast-setting can save you time by eliminating the need for a form. Instead, simply place one flat trowel against the side of the repair and hold it there for five minutes to act as a “form.”

It’s important to check your work area for moisture and debris frequently. This will prevent damage and ensure a good bond between the new and existing concrete. In addition, it’s important to clean your tools before and after using them.

Whether your repair project is large or small, it’s important to get it done right. By following these tips, you’ll be able to avoid problems and finish your concrete repairs with confidence.

Concrete structures are exposed to a wide range of conditions and stressors that can lead to damage. Whether it’s cracking, spalling (flaking or peeling), or structural issues such as settling or ground movement, these problems need to be repaired as soon as possible to protect the safety and longevity of the structure.

It’s important to recognize the signs of deterioration and take corrective action at the right time to save money in the long run. For example, repairing cracks in the surface of a concrete product is one way to address minor issues but identifying the underlying causes and taking steps to prevent them from occurring again can save significantly more money in the long run.

Safety measures include wearing protective equipment and ensuring that all tools are in good working condition before use. Also, proper training can help reduce accidents and injuries. It’s vital to know how to properly operate machinery, like concrete mixers and power tools, to minimize potential hazards. Additionally, all employees should be trained in the safe handling of all products used on the job site.

During the concrete repair process, it is important to keep all work areas clean and dry. This will minimize the pull of moisture from freshly applied concrete, which can affect bond and long-term durability. It’s also a good idea to cover the repair area with a damp burlap sheet or plastic to avoid contamination and promote a quick curing process.

Another important factor in ensuring a durable concrete repair is choosing the right material. Many repair materials are formulated to achieve high early strengths but this can be at the expense of long-term durability. It’s important to select a material that has a balance of strength and durability.

Another method for concrete repair is a system called PolyLevel, which uses a two-part polyurethane polymer to fill voids and lift slabs back to their original position. This is a noninvasive, quick, and aesthetically pleasing solution for repairing sinking concrete surfaces. This is especially useful for commercial and residential applications. It can be injected through pencil eraser-sized holes and expands into a structural foam that compacts the soil.